- • The Pug Mill/Ash conditioner applies to many industries. Where pollution control is a factor, the mill effectively blends dust recovered from such equipment as an electrostatic precipitator, mechanical collectors, and bag houses with Various liquids, thus allowing transport without the particulate matter escaping into the air. The Pug Mill/Ash conditioner also lets you recover valuable elements such as lead, iron, and copper and return them to the process stream. This is especially beneficial in sintering, as it returns the recovered dust to the process providing a closed circuit.

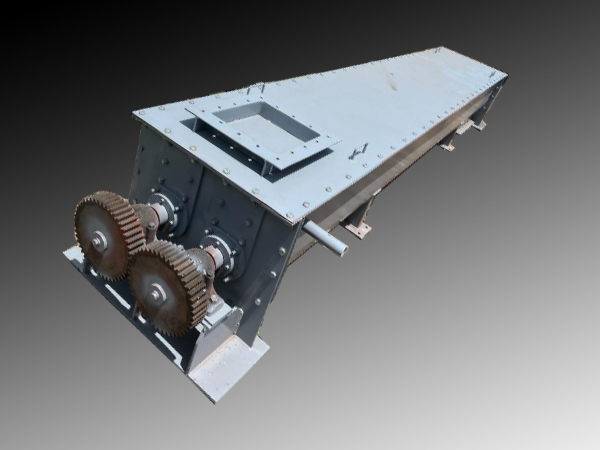

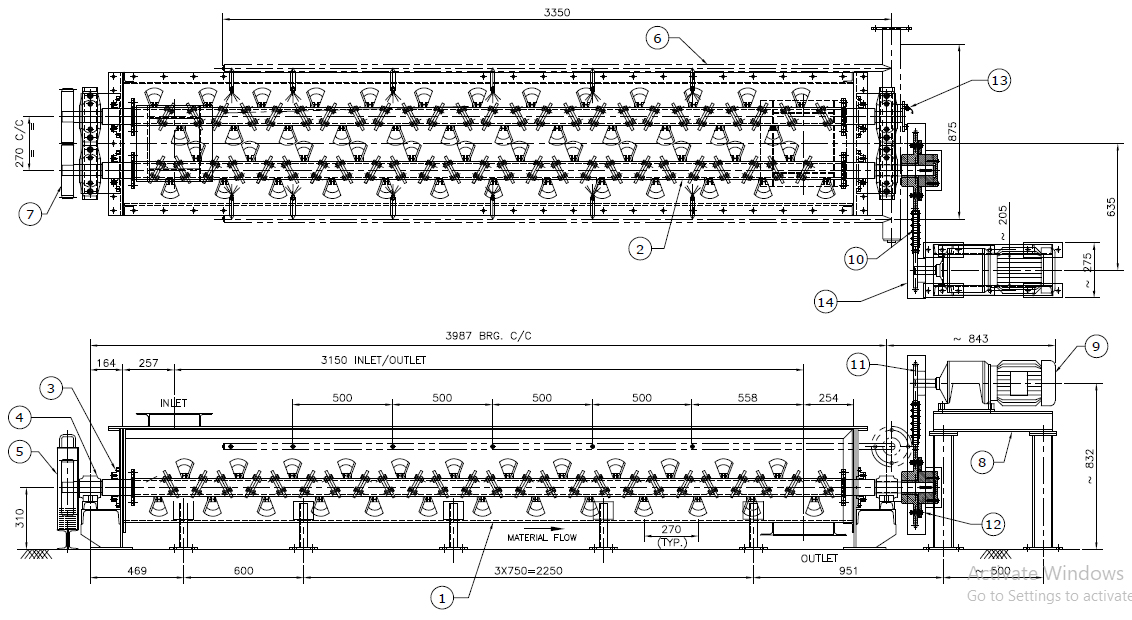

- • Paddle blade formation is set to give the most efficient mixing action with water being added by an arrangement of atomized spray nozzles up to 30% by weight. All Conditioners are of the heavy-duty design, of single or twin shaft formation, the material of construction can be mild steel or stainless steel. Throughput rates depend upon the type and properties of the product being handled. The sleeve will specify the machine size, length, speed, and power to suit the actual plant and capacity requirements.

- • Supplied Pug Mills Up to 80 TPH.

- • Efficient Design, With Minimum Noise, Minimum Power Consumption.